- Home

- COMPANY

- PRODUCTS

- Testing Machine

- Electromechanical Universal Testing Machine

- Hydraulic Universal Testing Machine

- Automated Testing Systems

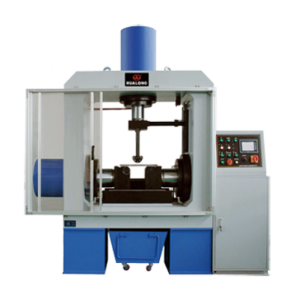

- Elastomeric Bearing Testing Machine

- Compression Testing Machine

- Impact Testing Systems

- High Temperature Creep Testing Machine

- Dynamic Testing Systems

- Torsion Testing Machine

- Bending Testing Machine

- Special Testing Machine

- Non-Metal Testing Machine

- Hardness Tester

- Metallographic Preparation Equipment

- Microscope

- Testing Accessories

- Testing Machine

- TEST OPTIONS

- SERVICE

- VIDEO

- CONTACT