1. Introduction:

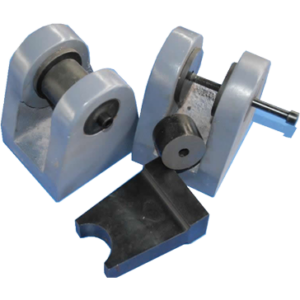

It is used primarily for testing highly elastic, soft, elastic specimens: plastics and elastomers, films, rubber, etc. with a tensile force of 20 kN.

Opening and closing is carried out by means of a lever. The scissor effect creates a prestressing force at the start of the test. Thanks to the scissor principle, an automatic clamping occurs with increasing tensile force – an advantage for specimens that narrow during the test. Equipped with a lock function.

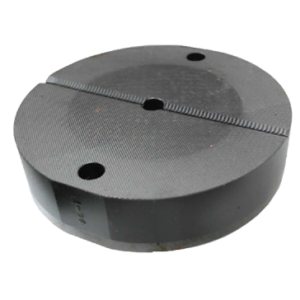

Clamping jaws have different types of surfaces:

-smooth (G);

-serrated pyramidal (Z);

-notched V-shaped (ЗV), for all types of round samples;

-wavy (B);

-roller with a serrated surface (RZ), used for specimens of the “bone” shape;

2. Specification:

|

Indicators

|

AT

|

W

|

KZ

|

ZV

|

AT

|

|

Clamping jaw surface

|

Smooth (B)

|

Gear (Z)

|

Round gear (KZ)

|

Toothed V-shaped (ЗV)

|

Wavy (B)

|

|

Max. tensile load, kN

|

Twenty

|

|

Opening size, mm

|

0-25

|

0-25

|

0-20

|

4-16

|

0-25

|

|

Sample width, no more than, mm

|

50

|

|

100

|

|

Jaw size, mm

|

25×50

|

25×50

|

Ø25×52

|

Ø 4 to 15

|

25×50

|

|

25×100

|

25×100

|

–

|

–

|

25×100

|

|

Dimensions. mm

|

160.2×123

|

|

When using sponges with a width of 100 mm, the tensile force is reduced to 10 kN.

|